MOLPIR has gradually expanded its operations through partnerships and direct OE deliveries to neighboring countries, eventually reaching almost all of Europe.

The company has its own research, development, and engineering team and cooperates with renowned experts in design, engineering, tool and mold development, as well as software and application development. This includes collaboration with the Slovak University of Technology, whose students frequently contribute fresh ideas to product development. MOLPIR’s in-house team processes customer requirements and market feedback, continuously developing new products and services that address current market needs.

Thanks to its strong technical and professional background, MOLPIR is capable of delivering comprehensive solutions regardless of the application. Its know-how, close collaboration with respected designers, use of modern technologies and prototyping equipment, extensive product testing and validation during development, rigorous quality control in mass production, cooperation with trusted manufacturers and component suppliers, and focus on after-sales service and customer support all contribute to the high quality and reliability of MOLPIR’s products.

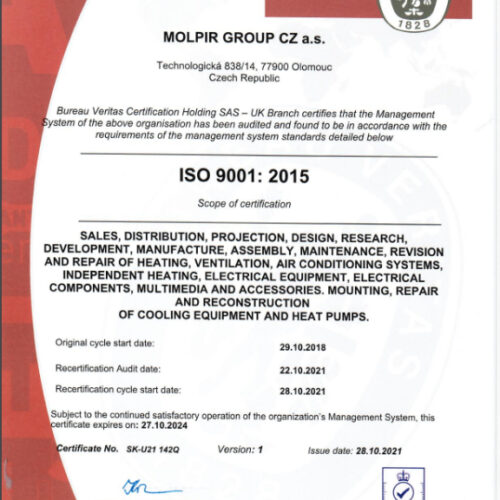

MOLPIR is ISO 9001 certified, and all components used comply with automotive, railway, and other relevant safety standards. As part of the development of integration and installation solutions, passenger safety is a top priority—therefore, all products, installation kits, and solutions undergo thorough testing, often in cooperation with seat and bus manufacturers in renowned European testing laboratories.

History

- 2025 – Introduction of a 12″ MOD monitor with Bluetooth headphones for trains.

- 2024 – Development and delivery of a 230V power outlet with current protection and integrated USB charger for trains.

- 2022 – Modular power socket with USB developed for railway applications.

- 2020 – Entry into the disinfection segment in response to the COVID-19 pandemic.

- 2018 – Introduction of wireless MOD solutions.

- 2016 – Beginning of in-house development and production of USB chargers.

- 2014 – Introduction of MOD systems for trains.

- 2013 – Launch of laser operations for sheet metal processing.

- 2011 – European representation for MSI FUNTORO.

- 2009 – Launch of the first digital MOD system in Europe.

- 2008 – New administrative and operational office opened in Olomouc.

- 2007 – Development and delivery of DVD player for ŠKODA Auto.

- 2004 – New administrative office with warehouse facilities in Bratislava.

- 1998 – ISO 9001 quality management certification.

- 1996 – Development and supply of air conditioning and heating systems for TATRA trucks.

- 1994 – Founding of MOLPIR GROUP CZ in Olomouc, Czech Republic.

- 1993 – Establishment of MOLPIR, s.r.o., with operations based in Bratislava.